GK. Rajesh

Scientific Advisor, Council for Nature Conservation and Environmental Protection, CONCEPT India

Sericulture has important socio-cultural implications. Studies have established large scale employment generation potential and high income generation potential of sericulture (Hanumappa, 1986). Jayaram et.al (1998) showed that every acre of sericulture practiced under irrigated conditions had a potential to employ 247 men and 193 women round the year. They have also shown that the small scale mulberry farms provided ample scope for employment of owned family labour and suggested its potential to solve the problem of seasonal unemployment. Lakshmanan et.al; (1999) found that female labour is quite dominant in all sericultural activities, to an extent of nearly 50%. Saraswathi and Sumangala (2001) observed that in the indoor activity of silkworm rearing women participation was as high as 94.67 % and that except for the peak period the entire sericultural activity is conducted using family labour. Most of the activities in silk production are in the informal sector and menial in nature. Thus about 90% of the employment goes either to the landless or to the marginal farming families that hire out these labour, or to the sericulture families (Sinha, 1989). While considering the price spread in the whole industry, it can be seen that 48% of it goes to farming sector, as illustrated below.

Inability to exploit export potential

India

Scientific Advisor, Council for Nature Conservation and Environmental Protection, CONCEPT India

This paper attempts to take a comprehensive look at the Indian silk industry and to identify the key issues of the sector. The impact of silk imports on domestic silk industry and sericulture are analyzed based on available data up to the year 2005. While the paper doesn’t offer any solutions for the problems, a few issues are thrown up which call for immediate research attention. The available (very few) studies on the economic issues of Indian silk industry are reviewed. The analysis has been restricted up to the year 2005 considering the fact that no much change has taken place in the industry since then.

Silk has a miniscule percentage of the global textile fibre market- less than 0.2%. But this figure can be a gross under-estimation, since the actual trading value of silk and silk products is much more. The unit price for raw silk is roughly twenty times that of raw cotton. The annual turnover of the China National Silk Import and Export Corporation alone is US$ 2–2.5 billion (ITC Silk review, 2001).

Sericulture and silk production are labour-intensive at the village level, employing both men and women at all stages of production (note-1). In China India

Sericulture in India – it’s past and present.

The silk trade flourished in India during the medieval period. Under the Moughals, silks from Kashmir and Bengal were exported mainly by the Moors, who during the 14th and 15th centuries transmitted it to Europe (Nanavaty, 1990). The British had identified the qualitative shortcoming with Indian silk and tried to improve it by bringing experts to modernize the rearing and reeling techniques. In 1771, the ‘China Bengal . In fact, the overseas market responded very favorably to the first consignment of the new technology in 1772 (Ray Indrajit, 2005). The government was also successful in diffusing Chinese worms in sericulture. Another breakthrough was achieved in the sphere of the production system. The government successfully organized sericulture as a cottage industry. The industry’s technology and organization were thus thoroughly reformed by the close of the eighteenth century in tandem with the requirements of the European market. Consequent to the abolition of British East India Company’s monopoly on private trade the company wound up its silk trade in 1833, leaving it to private entrepreneurs. During the last quarter of 19th century Bengal silk began to decline due to lack of proper organization, husbanding authority and the absence of technical know how (Ray Indrajit, 2005).

Hanumappa and Erappa (1988) cites sericulture development in the princely state of Mysore as an example of the crucial role the state can play in augmenting the sources of rural income. Sericulture flourished in Mysore Bengal . Japanese and Italian silkworm strains were imported and experts hired from these countries (Nanavaty, 1990). Spread of diseases during 1866 and the world depression in 1929 along with competition from imported silk and rayon lead to downfall of Indian silk industry on the eve of World War II. A tariff protection commenced from 1934 to save the industry from cheap imports of silk (National Commission of Agriculture, 1976). Durng the World War II, the Indian silk industry again surged, mainly due to demand from the Allies for silk for manufacture of parachutes (note- 2).

The first authentic inquiry into the conditions of Indian silk industry was undertaken in 1914-15 by H. Maxwell Lefroy and E. C. Ansorge (Lefroy and Ansorge, 1915). In a report they observed that the industry was scattered and unorganized producers were subjected to exploitation. They suggested formation of a central organization to address the needs of the industry (Lefroy and Ansorge, 1915). Subsequent recommendations by a Silk Panel in 1946 lead to the formation of the Central Silk Board in 1949.

Central Silk Board (CSB) is a statutory body, under the administrative control of the Ministry of Textiles, Government of India. One of the earliest commodity boards to be constituted by the Government of India, the Board coordinates the development of sericulture and advises the Government on policies governing export and import. It has the responsibility for pre-shipment inspection of silk goods exported from the country. The Board is also responsible for organizing sericultural research, training, basic seed (egg) production and collection of statistics pertaining to sericulture and silk industry (National Commission of Agriculture, 1976 and Gopalachar, 1978).

The Central Silk Board (CSB) established a number of sericulture research institutions in 1960s. With systematic efforts, it became possible in 1970s to develop a technology suitable for tropics. New mulberry varieties coupled with agronomical practices were made available to the farmers. Packages of practice were developed for silkworm rearing, besides realising new bivoltine races. Popularisation of the bivoltine hybrids was given priority. Since seed preparers started using bivoltine as a male parent for the preparation of cross breeds, the traditional poor yield crosses have been replaced to the extent of 85%. Consequent to this, mulberry sericulture was spread to non- traditional states like Kerala, Maharashtra, Rajasthan and Gujarat in the 1980s. While other crops (grains) perish due to very little precipitation, mulberry survives such acute situation where ground water is also not available for raising the crops, thus providing subsistence to a large number of farmers (National Commission of Agriculture, 1976).

Currently in India mulberry silk is chiefly produced in 5 states viz. Karnataka, Andhra Pradesh , Tamilnadu , West Bengal and Jammu & Kashmir, contributing to about 99% of the total mulberry silk produced. Interestingly, the states of A.P and T.N with almost no silk production during 1960 (Vasumathi, 2000), currently occupy the second and fourth position respectively. West Bengal at present contributes about 11.8% of the total cocoon / silk production, while Karnataka contributes the lion's share (43.95%) with Andhra Pradesh and Tamilnadu contributing 38 % and 4 % respectively. Production statistics up to 2005 is furnished in table 1.

Inability to exploit export potential

Table 2 gives India’s export, import and demand supply gap. The annual production of raw silk in India India

Table 3 gives India’s export earnings from silk (all commodities) over the period 2000 to 2005. It is seen that though the silk exports showed a compound growth rate of 7.95% over the years, its percentage share in total textile exports from the country has been stagnant over the years. Table 4 gives the value of silk and other textiles imported by India over the years. The percentage share of silk in the total textiles import has increased over the 6 years by 5.7%, whereas the net foreign exchange earning from export and imports has remained stagnant.

From the above analysis it is clear that even after being the second largest producer of silk, India contributes only 16% of global silk production and it is the largest importer of rawsilk. Impact of cheap imports on domestic industry

Apart from India

The data furnished in table 4 reveal that the rawsilk imports to India increased from 7896 tons in 2001, to 10506 tons in 2002, which is a 33% increase in one year. During the subsequent year the domestic silk production fell by 5.6% (from 17351 tons of 2002 to 16369 tons of 2003).The domestic silk production further fell by 10% (from 16369 tons of 2003 to 14620 tons of 2004).

Table 5 compares the annual growth rate in rawsilk imports for five years from 2000 against the performance of Indian sericulture industry and reeling sector to generate an idea about the comparative dynamics (Note:3). It is seen that the growth rate of silk imports were very high from 1999 to 2003 except for 2000-01. The growth rate in the value of imported silk (in Indian Rupee terms) has been lower than that of quantity of imports. The prices of domestic rawsilk and cocoon are observed to be worst affected during the years 2001-02 and 2002-03, the periods in which imports grew very high and prices of imported silk kept falling. Thomas et. al (2005a) showed that the cocoon price get influenced by the yarn prices with a lag of six to ten days. From the table 5, it is clear that during 2001-02 and 2002-03 when domestic rawsilk prices fell by 4.9% and 24.1 % respectively, the cocoon price also fell by 4.8% and 10.8%. This has impacted on cocoon production, lowering it by 8.2% and 8.4% during 2002-03 and 2003-04 respectively. The data shows that the effect of imports influenced the mulberry plantation also. During 2002-03 in Karnataka alone 23% of the existing mulberry plantations were uprooted and in the subsequent year another 10% uprooting occurred. 6780 charka reeling units have closed down over the six years where as the number of cottage basin reeling units have increased by 846 only. The number of multi-end reeling units has also fallen by 59. This means considerable labour displacement from the charka sector during the six years which is not likely due to up gradation of the charka units into cottage basins.

The fall in: prices, quantity of cocoon production and mulberry area and labour displacement from the reeling sector cannot be completely attributed to the rawsilk import. Many other socio economic factors could be at play. However it is seen that subsequent to a protectionist intervention of the government during 2003, the quantity of imports fell by 2.3%, domestic rawsilk prices increased from Rs. 805.00 to Rs. 984.00 per kg (22.2% growth) and cocoon prices increased by 17.8% (note-4). During the subsequent year the quantity of cocoon production showed slight improvement (2.2% growth) and the mulberry uprooting rate came down from 10.26% to 2.23%. This indicates that the silk imports have had a deleterious effect on the domestic sericulture.

It is generally held that the imported rawsilk is consumed by the powerlooms since power looms require qualitatively superior and strong yarn for the warp and the relatively poor quality local yarn is fit for the weft only (Thomas e.al, 2005b and Vasumathi, 2000).

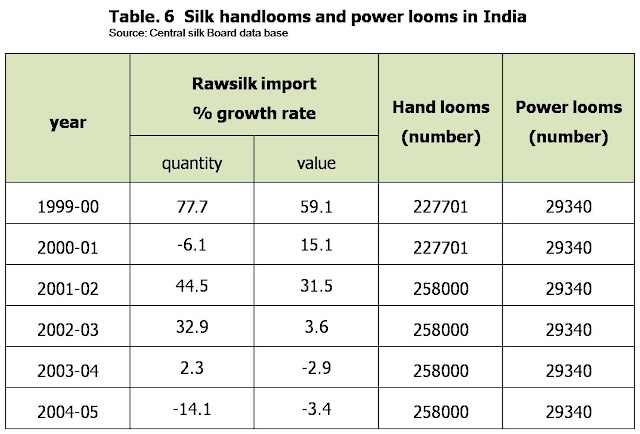

Table 6 gives the growth rate of rawsilk imports over 6 years from 1999-00 against number of handlooms and power looms in the country. It is seen that the number of power looms have stagnated at 29340 over the years and the number of handlooms have increased by 30299 during 2001-02. The rawsilk imports have been in the increase. Thomas et.al. (2005b) found that only 50-53% of the yarn requirement of the power loom sector is met from Chinese imports. Thus it may be inferred that a considerable portion of the imported yarn is being absorbed by the handloom sector also, which is traditionally known as the sole consumer of charka silk (Vasumathi, 2000).A study conducted by Thomas et.al. (2005b) revealed the pattern of rawsilk usage as given in table 7

Thomas et.al. (2005b) also have shown that the imported Chinese silk is superior to the locally available silk with respect to denier, cleanness, cohesion, gumming losses and uniformity. Table .8 presents a comparison of imported silk with local silk based on these attributes.Naik .G & Babu (1993) have estimated that the total high quality silk production in India could meet at the most 60 percent of the estimated demand and have cautioned about the negative implications of the Chinese raw silk on the development of Indian silk industry. They also noted that diversion of imported silk into domestic sector benefit only the consumer. By avoiding this diversion, the demand for domestically produced high quality silk would have increased the good health of the industry. Some of their recommendations for amelioration of the current situation include - improvement in research and extension facility, adequate supply of inputs and proper marketing facilities and modifications in the production system.

Summary and conclusion

In spite of its small volume in global textile production, silk has importance in developing economies primarily because of its favorable socio economic consequences. The development of sericulture had been the states priority in every country. The case of Indian sericulture is no exception to this. A number of regulations were made in favor of the farm sector. Many ambitious projects were launched and a large number of technologies made available. In spite of all this, poor productivity, poor quality, high cost of production and labour intensity continue to be the hall marks of Indian silk industry. In order to cater to the needs of sophisticated power-looms and in response to the relaxation in exim policies, large quantities of high quality silk has been imported at prices lower to local silk. This has disrupted the domestic silk reeling industry and sericulture farm sector, leading to considerable labour displacement. Protectionist government interventions have temporarily eased the problem. But how long tariff protections could help the domestic industry is a question. Data shows that imported silk is finding place even on the traditional handlooms, clearly demonstrating its comparative advantage. The recent data shows that the price of imported silk is in the increase while the government has announced a slash in customs duty of raw silk imports from 30% to 5%. While the farmers and reelers staged an agitation the weaving sector welcome the gesture. Thus the industry is divided in its opinion on cheap imports, indicating the necessity for the government to take appropriate policy decisions. Where does our comparative advantage lie? Is it in the sericulture farm sector or in the silk weaving industry? If the farm sector has to survive, is it sufficiently equipped to take up the challenge of ensuring high quality raw material supply? If this is ensured, is the silk reeling sector capable of absorbing the high quality cocoons? These are the questions that the Indian silk industry has to answer before proceeding any further.

Notes

- While considering patterns of location of sericulture, Federico (1997) observed, “……. . the ideal environment for silkworm raising was densely populated area, with dispersed dwellings and few opportunities for non-agricultural work. It is not surprising that sericulture did not develop at all where the population was scarce and labour, expensive (as in the United States) or where people lived in large villages far from the fields (as in the interior of Sicily or Spain)……..Silkworm raising does not need strength but does require much care and caution in handling the worms, which are exteremely delicate animals, very sensitive to any form of ill-treatment and /or sudden change of temperature. Therefore sericulture was traditionally women’s work, while men cultivated the mulberry trees and sometimes helped to transport the leaves.”

- The industry in Mysore doubled its pre-war size. Mulberry acrage rose from 26500 to 80000. Number of filature basins in Mysore and Madras rose from 300 (in 1939) to over 2000 (in 1945). Filature silk production rose from 2300 kg(1937) to 137000 kg (1945) (Nanavaty, 1990)

- The majority of silk produced in India is through charka, the traditional reeling device and less sophisticated cottage basin reeling units. Semi and fully automatic reeling machines are used to produce high quality silk in Japan, Korea and China. Multi-end reeling machines have been developed and popularized in India to produce high quality silk which need good quality cocoons of uniform size and shape as raw material

- Antidumping investigations were undertaken by Directorate General of Anti-Dumping and allied Duties (DGAD&AD) on a petition by the reelers affected by the falling domestic prices. The designated authority imposed antidumping duty on landed goods so as to raise import prices to US$ 27.97 per kg.on all imports of mulberry raw silk of 2A grade and below originating in or exported from Peoples Republic of China. The duty came into force wef. 3rd July 2003. (Ministry of Textiles, Government of India, 2007)

REFERENCES

Gopalachar, A.R.S. (1978) 3 Decades of Sericultural Progress (Sericulture Industry in India Board , India

Hanumappa, H.G. and Erappa, S. (1988) Sericulture in Princely Mysore Trivandrum

Hanumappa,H.G., and Erappa, S. (1986) Economic issues in sericulture: Study of Karnataka. ”Economic and Political Weekly” 20(31)1322-1324.

ITC Silk Review (2001) http://www.intracen.org/

Jayaram, H., Mallikarjuna, V., Lakshmanan, S., Ganapathi, Rao, R. and Geetha, Devi, R. G. (1998) Labour Employment Under Different Mulberry Farm Holdings-a Comparative Study. Indian Journal of Sericulture, 37(01), p52-56.

Lakshman, S; B. Mallikarjuna., R. Ganapathi Rao; H. Jayaram and R.G. Geetha Devi (1999) An empirical investigation on labour productivity in mulberry sericulture. “Indian journal of Sericulture” 38(1) 48-52

Lefroy, MaxWell, H. and E.C. Ansorge (1915) Report on an Inquiry into the Silk Industry in India Calcutta

Mattigatti, R; Srinivasa, G; Iyengar, M.N.S; Datta, R.K. and Geetha Devi, R.G (2000) Price spread in silk industry- an economic analysis. “Indian Journal of Sericulture” 39(2) 163-64

Naik Gopal and Babu KH, (1993), Demand and Supply Prospects for High Quality Silk,Oxford & IBH Publishing Co. Pvt. Ltd, New Delhi

Nanavathy, M. (1990) Silk, Production, Procesing and Marketting, Pub: Wilely Eastern Ltd.

National Commission of Agriculture (1976) Report of the National Commission on Agriculture, sericulture and apiculture; Government of India, Ministry of Agriculture and Irrigation, New Delhi. P.447-480

Ray, Indrajit (2005) The Silk Industry In Bengal During Colonial Rule: The De-Industrialisation. Thesis Revisited. Indian Economic Social History Review; 42; 339

Saraswathi, J.M. and Sumangala, P.R. (2001) Participation of Farm Women In Sericulture Enterprise. “Indian Journal of Sericulture” 40(1) 86-91

Sinha, Sanjay (1989) Development Impact Of Silk Production, A Wealth Of Opportunities. “Economic and Political Weekly,” January 21, 157-163.

Thomas Jacob, Arun Kumar, K.S, Reddy and Lalith. A (2005a) Quantification of Relationship Between Silk Cocoon and Silk Yarn Prices- an Application of ARIMA Model. In Reading Bangalore

Thomas, Jacob., Arun Kumar, K.S, Lalith. A and Reddy.S (2005b) Requirement of Quality Silk Yarn of The Power Loom Sector-A Quantitative Analysis. In Reading Bangalore

Tikku, M.K. (1999) Tangled Threads Silk Growers and Imports. Economic and Political Weekly, March 6-13, p. 578

United Nations (1994) “Silks In Asia,” Economic and Social Commission for Asia and the Pacific.

Vasumathi ( 2000) An Analytical Study Of The Silk Reeling Operations In Karnataka.

.

.

1 comment:

Dear Mr. GK Rajesh

The article is really very good and gives a good insight into the present status of Indian sericulture. It would have been wonderful if you could have provided latest statistics.

One good news is TNAU has started the B.Sc. (Sericulture) course during this academic year. Already 24 seats out of 30 seats has been filled in the I phase of counselling itself.

Good days

C.A. Mahalingam

TNAU, Coimbatore

Post a Comment